Presentation of a new chemical product.

Thus, JBS Couros decided to work together with the two most significant sectors for the leather production chain in terms of potential environmental impact, the Livestock and Chemical Industry, and align what contributions can be made to establish joint leadership in sustainability.

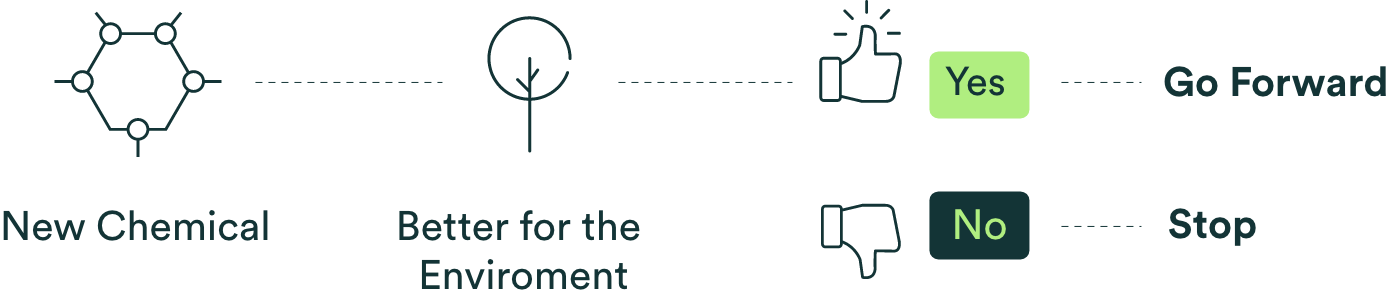

RTC is a system that collects and analyzes information on environmental parameters related to chemicals, as well as their respective application in recipes for the leather production. The result of these analyses serve as a core criterion for decision making regarding use of the proposed chemical.

Hazardous Substances

Hazardous Substances

Presentation of a new chemical product.

Submission of laboratory results and respective “SC” reports.

RTC Analyses.

Presenting Sustainability Performance Results and Chemical Proposal to Technical Board.

Assessment process in the decision making structure of JBS Couros

RTC: What it is?

It is a comparative analysis tool that collects and evaluates four environmental parameters related to chemicals, as well as their respective application in recipes for the production of leather articles.

It is an analytical tool developed by JBS Couros to assess the impact of introducing new chemicals into the company’s formulations and to support the company’s decision-making structure regarding the adoption of new chemical specialties.

What is not RTC?

RTC is not a system for analyzing chemicals in other manufacturing processes, as it was specifically created for the leather production process.

RTC does not operate as or replace a comprehensive Life Cycle Assessment (LCA).

What will the RTC be used for?

It will be used to evaluate the environmental performance of chemicals used in the leather production process. The results will contribute to JBS Couros’ decision-making structure regarding the inclusion of new chemical specialties in the company’s formulations. In this way, JBS Couros firmly integrates the environmental dimension into the decision-making process for selecting new chemicals.

To which types of chemicals does it apply?

As of its effective date, the RTC will apply to new chemical specialties being evaluated/proposed for use in JBS Couros formulations.

“New” refers to specialties that are not yet in use by JBS Couros.

In its first version, the chemicals analyzed will be limited to those used in the wet process stages:

* Liming

* Tanning

* Retanning

Will chemicals already being used in JBS Couros processes be analyzed by the RTC?

The RTC will apply exclusively to new chemical specialties. JBS Couros uses several methods to evaluate the environmental performance of its leather, such as life cycle assessments, biogenic carbon quantification, restricted substances control, among others. However, it is important to clarify that, as the RTC relies on building a database containing the required analysis results of chemicals already supplied, suppliers must provide these results. Otherwise, the introduction of new products may be compromised, and the supplier will be considered “non-compliant” by JBS.

What are the environmental parameters required in RTC?

* Environmental Impact Categories

* Biodegradability

* Hazardous Substances

* Biogenic Carbon

Why were these parameters selected?

JBS Couros consistently strives to stay up to date with market needs and scientific trends within the sector. For this purpose, a study was conducted to identify the environmental aspects considered most relevant to leather, which served as the basis for selecting the analyzed parameters.

Why do the environmental parameters have different weightings?

The assigned weights reflect a detailed analysis of the trends and expectations of suppliers and customers regarding environmental criteria. Based on this analysis, JBS Couros formulated its vision on how each environmental aspect should be valued within the RTC.

Where can I find the methodologies required for the analysis of the environmental parameters selected in the RTC?

The methodologies required for the analysis of the environmental parameters selected in the RTC can be accessed through the RTC Technical Guide, available here on the official RTC website.

Why were the selected methodologies chosen?

The chosen methodologies comply with the most widely accepted and recognized technical-scientific standards at an international level and are broadly utilized within the industry.

Why did JBS decide to develop the RTC?

JBS Couros is always striving to make the leather of the future better than today's, constantly working to surpass it in quality and sustainability. Recognizing the crucial importance of chemicals in the leather production chain, JBS Couros is committed to actively engaging with the chemical industry to identify and implement more environmentally responsible alternatives. This engagement is key to turning the vision of improved leather aligned with sustainability principles into reality. Additionally, JBS Couros considers it essential that decisions in the manufacturing of its products take environmental impacts into account. The lack of standardization in the industry regarding sustainability is a significant challenge, and JBS Couros believes it can contribute to the creation of standards and practices that promote a more uniform and effective approach throughout the industry. Thus, the company seeks not only to improve its own processes but also to contribute to a more robust and consistent sustainability standard across the entire industry.

How should suppliers provide the results of the environmental parameters analyses to JBS?

Suppliers should complete the spreadsheet sent via email by the JBS Couros Sustainability team, which is also available for download on the RTC website. They should then send it along with the analysis lab reports to the email: rtc@kindleather.com.

What should suppliers not do?

* Suppliers should not submit their results through any other means than the aforementioned spreadsheet and the email rtc@kindleather.com.

* Environmental parameter analyses should not be conducted using methodologies other than those required in the RTC Technical Guide.

* Results should not be submitted without the proper laboratory reports.

* After January 6th, no new chemical should be proposed for use without its supplier having delivered the results of the analyses requested by the RTC and without the analysis via the RTC having been conducted by the JBS Couros team.

In a recipe development, it is common to have multiple versions. Considering this, how many RTC analyses will be conducted?

The RTC analysis will be conducted based on the first version of the recipe that includes the proposed new chemical for use.

Will one chemical be compared to another?

No, the RTC analysis will be conducted based on a specific formulation and will therefore consider how each chemical influences the dynamics of the recipe. Due to the complexity and unique interactions between the components of each formulation, it is not appropriate to compare in isolation, one chemical to another.

Why did JBS choose four parameters and not just one?

JBS Couros believes that sustainability cannot be measured by a single indicator but rather by a diverse set of criteria. Therefore, it is essential to analyze it from multiple perspectives to obtain a comprehensive and more accurate assessment.

If suppliers will need to analyze chemicals already under use by JBS, what will change starting from January 2025?

In January 2025, the submission of analysis results will become mandatory for all suppliers before any testing of new chemical specialties is initiated at JBS Couros R&D.

To report the percentage of “active substance,” can the supplier use the “Certificate of Analysis” (CoA) / TDS, or is another external laboratory report required?

The internal certificate/report is sufficient.

Are bisphenols part of the RTC analysis?

No, however, since the presence of bisphenol is widely discussed in the leather business, JBS Couros included it in the data collection spreadsheet in case the supplier wishes to report it. It is important to emphasize that this value is not mandatory and it will not be considered in the RTC calculation.

Is the “EN 16640:2017” method required for Biogenic Carbon analysis equivalent to the “ASTM D6866” method?

These methods are similar but not equivalent. Both use radiocarbon analysis, but ASTM D6866 offers greater flexibility in analysis conditions. In the initial phase, JBS has determined that EN 16640 would be the better option

The OECD 301 guideline, required for the Biodegradability analysis, includes six different methods (301-A, -B, -C, -D, -E, -F). Which one should be used?

The differences between the methods are mainly due to the characteristics of the sample to be analyzed, that is, whether the chemical product is concentrated, solid, soluble, etc. Our suggestion is method B, as it can be applied to different types of chemicals. However, all methods are accepted, provided that the laboratory report is presented along with the result.

I don’t have primary LCA data. How should I classify my chemical among the available proxies?

To select the proxy that best represents the chemical product, the substance with the greatest mass in the composition should be considered.

Which proxies does JBS Couros use?

JBS Couros uses the list of “Environmental Footprint 3.1” proxies, specifically those contained in the “EF 3.1 - Chemicals” addendum. This methodology is aligned with Ecoinvent and follows the same principles.